by MP Divakar, PhD, Stack Design Automation

Technical Editor, Electronics Cooling Online

Prior to designing the requisite thermal management solution, engineers routinely calculate the junction temperatures of active and passive components using various methods at their disposal –finite difference grids, lumped parameter models, finite element methods, etc. The junction temperature of an electronic component depends on the ambient temperature and the temperature gradient in the ‘enclosure’ the component resides in. The surface temperatures of ‘enclosures’ receive less scrutiny in comparison to the junction temperatures of components, but need to be given equal attention. Electronics Cooling has many publications on various methods to calculate component and surface temperatures under air- and liquid-cooled conditions; for example this article which discusses calculating component temperatures in an air-cooled enclosure.

Due to safety restrictions, the maximum surface temperatures of enclosures are controlled by various standards organizations. ASTM, Telcordia, IEC, etc., are some of the standards entities to stipulate the maximum touch temperatures of appliances as well as the duration of touch. NASA documents an approach to calculate touch temperatures based on the human threshold to pain for both hot and cold temperatures.

With the proliferation of wearable devices such as smart watches, personal health and fitness gadgets, the definition of safe touch / wear temperatures is of primary importance to design engineers. This gets more interesting if one were to design an energy-harvesting wearable solution designed to utilize heat generated by the human body. Thermopiles exploit the temperature gradients to convert thermal energy into electrical.

The average human body temperature ranges between 37 to 38°C. To realize a 10°C temperature gradient, human bodies prefer a 27°C ambient temperature as opposed to 48°C! In fact, one gets very uncomfortable and minimally functional at temperatures higher than 105°F (40.5°C). Various governmental bodies such as the US Labor Department’s OSHA (Occupational Safety & Health Administration) and Consumer Product Safety Commission (CPSC) also stipulate limits on safe working / operating temperatures. In fact, at temperatures exceeding 115°F (46°C), OSHA categorizes the risk level as extremely high.

Therefore, to get the maximum temperature gradient for energy harvesting, a cooler ambient temperature is desired for wearables harvesting thermal energy from the temperature gradients. This is also beneficial to the SoCs (System on Chips) used in wearables as they can be run at higher duty cycles. However, the case temperatures of wearables in all cases must still be below that of human body temperature. Exceeding this limit and with prolonged use leads to skin burns of various degrees depending on the severity. Product recalls can be costly and embarrassing and unfortunately not too uncommon (for example, Intel’s Basis Peak Watch recall few weeks ago).

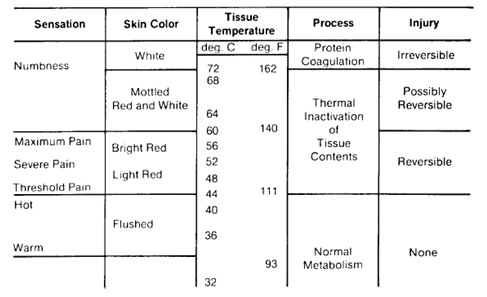

ASTM C1055 (the Standard Guide for Heated System Surface Conditions that Produce Contact Burn Injuries) recommends that surface temperatures remain at or below 140°F. The reason for this is that the average person can touch a 140°F surface for up to five seconds without sustaining irreversible burn damage.

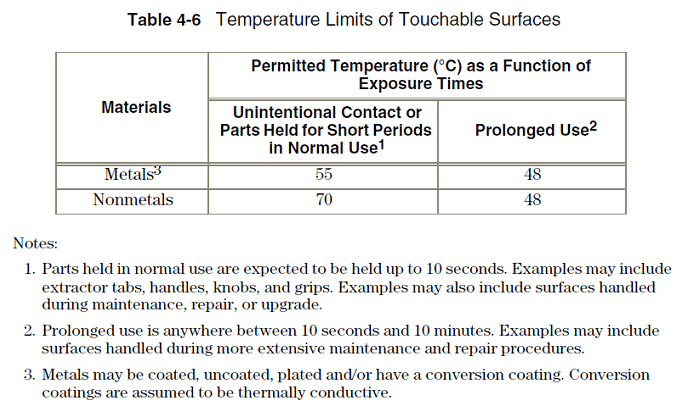

Telcordia GR-63 for telecommunications appliances categorizes contact surfaces by material types –metal and nonmetals, shown below. It distinguishes between short periods of contact time and prolonged use.

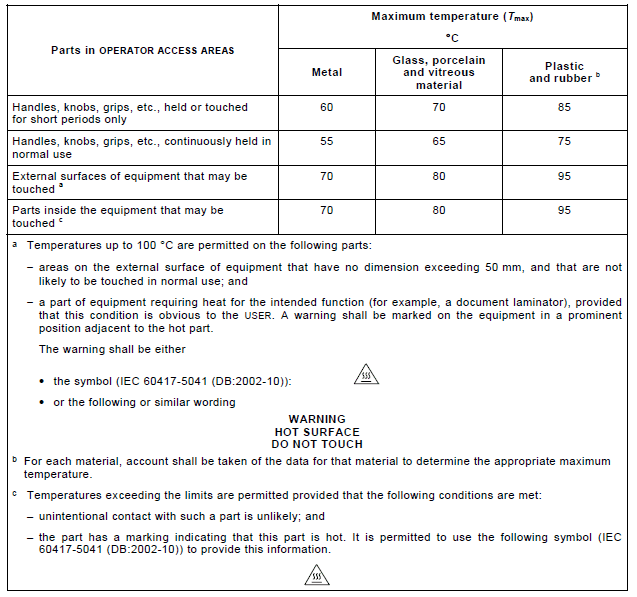

IEC’s 60950-1 (2005), which is the most utilized standard by those working on consumer electronics devices, provides further granularity between material types. As shown below, the maximum surface temperature is the lowest for metallic surfaces and maximum for plastics and rubber.

In summary, if you are tasked with calculating surface and/or wear temperatures of ‘enclosures’ with active and passive components, use the most accurate method at your disposal but with full cognizance of the end application.

While it is straight forward to compute surface temperatures of enclosures housing various computers and networking appliances, it is more challenging to do so for wearable electronics. Various factors influence the heat transfer from the wearable device to the body in contact. Skin’s surface conditions, oiliness, moisture, etc., need to be included in contact resistance calculation. For all of your foregoing considerations in calculating temperatures, visit the resources and publications Electronics Cooling has to offer.